Benefits of resin coated sand as moulding sand of casting precoated sand:

Castings can be produced with close tolerance and with very minimum machining allowances along with excellent surface finish.

Self life of the resin coated sand is unlimited.

Hollow cores can be produced.

Lump free sand.

No crack of core or shell.

High transverse strength.

Low density of Raysons Resin Coated Sand gives maximum output.

Less core weight.

Release agent gives maximum output without breakages.

Fast curing of Raysons Resin Coated Sand gives high production with uniform baking of sand.

Special fine Resin Coated Sand doesn’t require refractory coatings or core paint, achieves better surface finish.

Low rate of gas generation.

resin coated sand as moulding sand of casting precoated sand Cast iron and cast steel

Overview

Quick Details

- Place of Origin:

-

Hebei, China

- Brand Name:

-

Yuchuan

- Model Number:

-

50-100mesh 70-140mesh

- Application:

-

Cast steel

- Shape:

-

Granular

- Chemical Composition:

-

SiO2

- Product name:

-

Resin sand

- Color:

-

Black,Yellow, brown, blue, green, pink,etc

- Material:

-

resin silica sand

- Usage:

-

casting

- Size:

-

50-100mesh40-70mesh

- Package:

-

50kg/bag,1ton/bag

- Purity:

-

99%

- Sample:

-

Available

- Type:

-

Adjustable performance

- Keyword:

-

Foundry sand

Products Description

resin coated sand as moulding sand of casting precoated sand Cast iron and cast steel

PRODUCT SPECIFICATIONS

Product name | Resin coated sand |

Place of Origin | Hebei,China |

Brand Name | Yuchuan |

Color | Black,Yellow,Blue, Green, Pink, Brown,Customizable colors |

Sample | Free Provided |

Material | Original sand,Resin |

Size | 50-100mesh 70-140mesh customized |

Application | Casting |

Customization | Available |

Appearance | Fine particles |

Product Overview

Resin coated sand

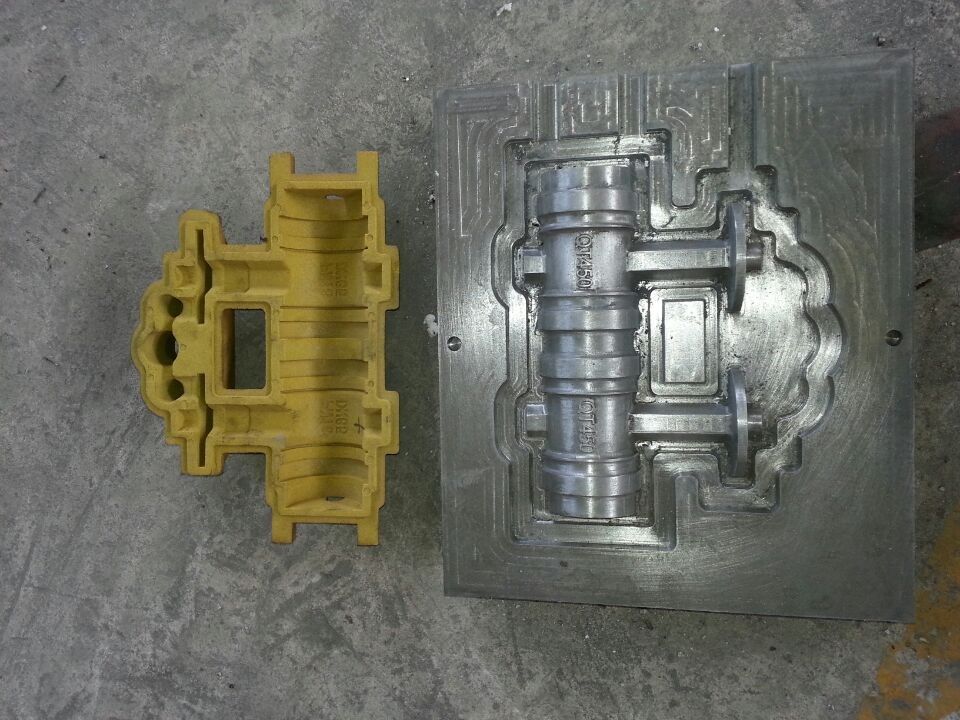

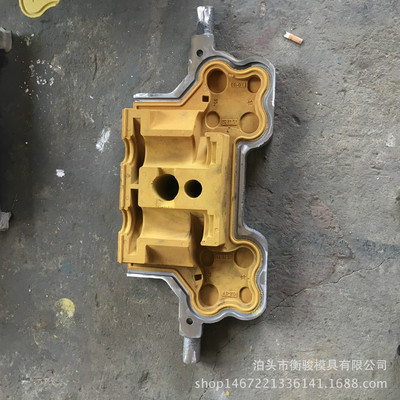

Resin coated sand is a method in foundry practices and produces a casting of high precise

dimensions, smooth surface, free of blow holes and devoid of casting defects.The surface of the sand is covered with a layer of solid resin film or sand. Cold and hot method of two kinds of coating process: cold method to dissolve the resin with ethanol, and in the process of mixing the mixture, so that the two covered in the sand surface, the evaporation of ethanol, Method to preheat the sand to a certain temperature, add resin to melt, stir the resin coated on the sand surface, plus aqueous solution and lubricant, cooling, crushing, screening coated sand. It is one of the best moulding sands for cars, tractors and hydraulic parts.

dimensions, smooth surface, free of blow holes and devoid of casting defects.The surface of the sand is covered with a layer of solid resin film or sand. Cold and hot method of two kinds of coating process: cold method to dissolve the resin with ethanol, and in the process of mixing the mixture, so that the two covered in the sand surface, the evaporation of ethanol, Method to preheat the sand to a certain temperature, add resin to melt, stir the resin coated on the sand surface, plus aqueous solution and lubricant, cooling, crushing, screening coated sand. It is one of the best moulding sands for cars, tractors and hydraulic parts.

FEATURES AT A GLANCE

Silica resin coated sand also can be used for many casting methods such as vacuum casting, VRH, LFC, investment casting, common

and resin sand. The fused ceramic foundry sand can be with many adhesives, greatly improving the quality of castings.

1. Production of low pollution coated sand, reduce the use amount of resin and curing temperature; improve coated sand's overall performance, especially in high temperatures; research and develop of pollution-free phenolic resin alternatives.and resin sand. The fused ceramic foundry sand can be with many adhesives, greatly improving the quality of castings.

2. Improve the regenerative capacity of coated sand.

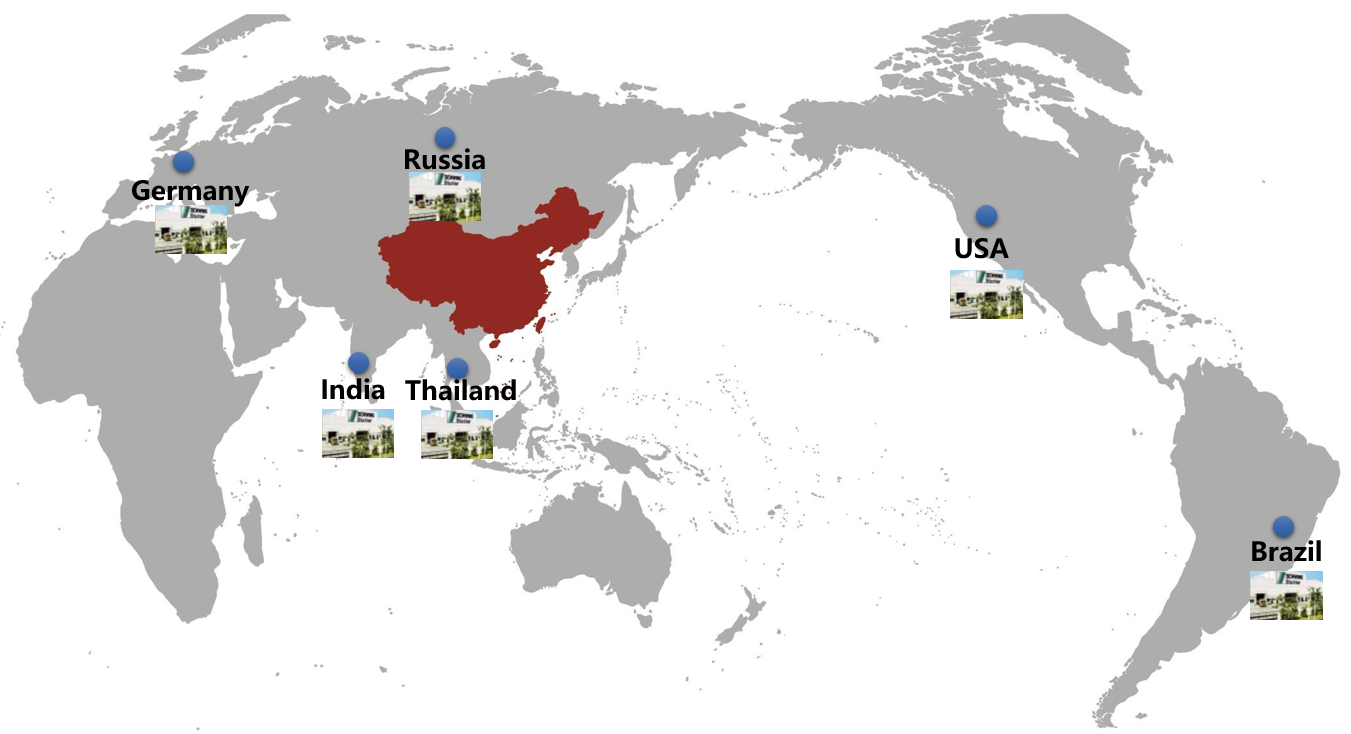

Company Profile

SALES AND SERVICE NETWORK

Contact Us

Email: yuchuankc2010@163.com

zuoyj199310@163.com

zuoyh199310@163.com

TEL: 008613284453768

TEL: 008613284453768

008615176900078